The news

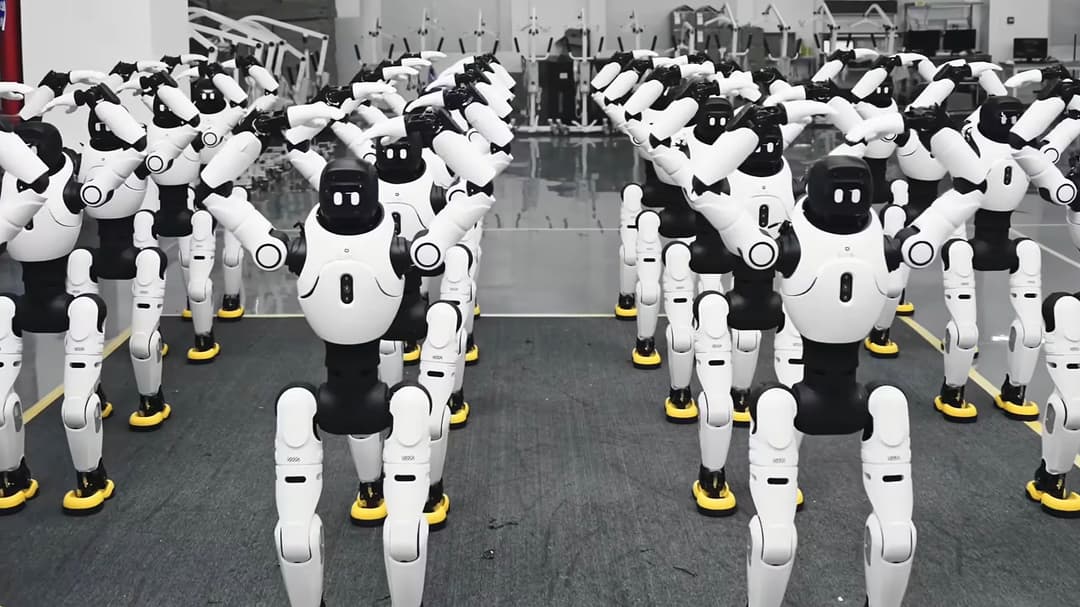

AgiBot announced the rollout of its 5,000th mass‑produced humanoid from its Shanghai production lines in early December 2025. The company attributes the volume to an industrialized manufacturing process and product diversification across three primary series — the A‑Series (full‑size), X‑Series (agile/compact), and G‑Series (task‑optimized). Public reporting and the company’s distributed press material indicate approximate per‑series counts at 1.7k, 1.8k, and 1.4k units respectively.

Where these robots are going

Deployed use cases reported include factory floor guidance and inspection, warehouse sorting and logistics assistance, commercial cleaning, fixed‑route security inspection, and demonstration/exhibition roles. AgiBot cites both private commercial contracts and pilot programs in logistics and retail, but independent coverage notes that detailed customer lists and long‑term performance metrics remain limited in public records.

Why this matters

Producing 5,000 units indicates a transition point: humanoid robotics is moving from low‑volume prototypes to repeatable, scalable production. For industry observers this means procurement cycles will shift focus from feasibility to cost of ownership, service logistics, and task‑level integration. The milestone does not, by itself, validate long‑term operational effectiveness — rather, it establishes supply capability.

Technical and operational caveats

Public materials emphasize reliability and incremental firmware and mechanical refinements. However, open reporting and community analysis highlight unresolved concerns: on‑site integration complexity, mean‑time‑to‑repair for field units, software update pipelines for fleet management, and compliance with region‑specific safety regulations. Independent verification of long‑term uptime or total cost of ownership has not been published.

Market context

AgiBot’s announcement arrives amid a broader push by multiple manufacturers to scale humanoid and general‑purpose robots. Analysts frame the 5,000‑unit rollout as part of a first wave of commercialization: volume production that tests downstream supply chains (service, spare parts, software updates) and market readiness for routine humanoid deployments.

Bottom line

AgiBot’s 5,000th unit is a factual milestone in production capacity; its strategic importance depends on deployment depth, operational reliability, and the company’s ability to support a distributed fleet. Expect follow‑up reporting to focus on contracts, uptime statistics, and third‑party validations rather than production totals alone.