Atlas is back and different this time. At CES 2026 Boston Dynamics revealed a production-ready Atlas meant for real work in factories and warehouses. This short profile explains the headline feature you need to remember, the first real use cases, and what Atlas actually adds to a shop floor.

Operational autonomy with integrated AI - The headline feature

Autonomy means Atlas can handle a full task or a chain of actions with less human handholding. It sees a change, it adapts, and it keeps working.

Atlas is built to do more than a single trick. It watches the scene, figures out the next step, and keeps going when things move or go wrong. That is a big difference from robots that only replay fixed motions. At CES 2026 Boston Dynamics showed Atlas doing sequences of work, not just demonstrating balance or agility.

Boston Dynamics has started working with Google DeepMind to bring better instruction handling to the robot. The goal is simple. Teach Atlas a task once and reuse that skill in similar jobs. That means less custom programming for each new line and faster setup when the job changes.

Why it’s a good thing

A robot that can deal with small surprises is far more useful on a real floor. Parts get shifted, coworkers move around, and the work cell rarely looks the same twice. Atlas is designed to keep working in that messy reality. That reduces the time engineers spend tuning robots and it reduces downtime.

What it does not solve yet

Atlas is not a household helper. It is not replacing skilled technicians. The robot will start with structured tasks that still need human oversight. Safety approvals, long term reliability, and cost remain big hurdles for rapid scale up.

Other notable capabilities

- Smooth, humanlike walking and balance for tight industrial spaces

- Robust hands and arms for part handling and positioning

- Practical power design for long shifts and quick swaps

TL;DR

- Production-ready humanoid shown at CES 2026

- Built for industrial and logistics tasks, not consumer chores

- Designed to run tasks with limited human intervention

- Backed by Boston Dynamics, Hyundai, and AI work with Google DeepMind

- Early pilots are in controlled factory environments

Known deployment cases

CES 2026 demo, Las Vegas

Boston Dynamics demonstrated Atlas doing task sequences on stage. This was the clearest public look at the production hardware handling a string of actions instead of single stunts.

Hyundai manufacturing pilots

Hyundai is an early partner. Atlas is slated to help with part movement and sequencing in factory settings. These pilots focus on predictable, repetitive steps where the robot’s balance and reach give real advantage.

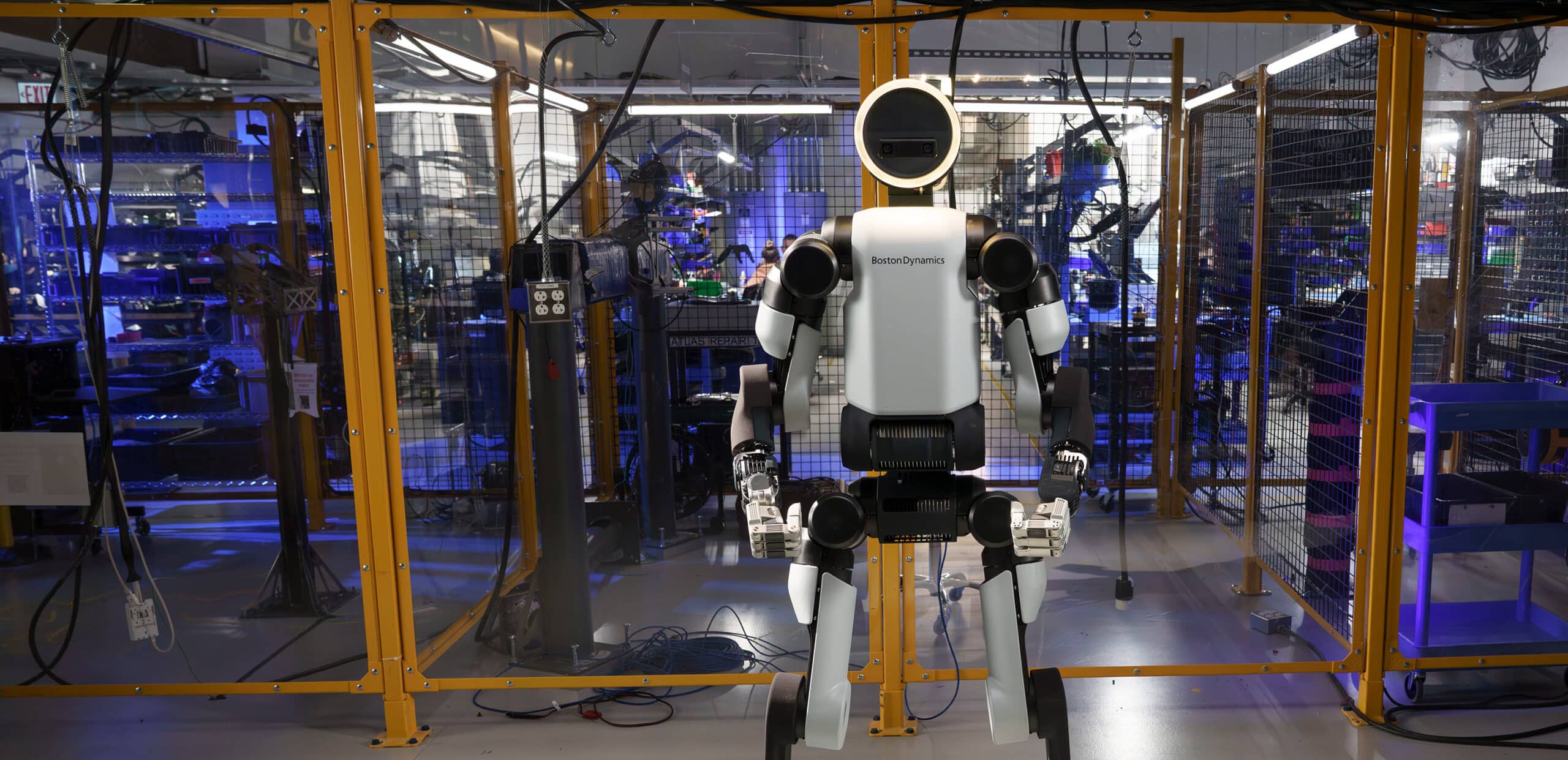

Boston Dynamics Atlas on a factory floor (Image credit: Boston Dynamics)

Google DeepMind research fleet

Atlas will be part of research programs that teach robots to follow higher level instructions and generalize skills. This work is aimed at making new tasks faster to deploy.

Announcement: https://bostondynamics.com/blog/boston-dynamics-google-deepmind-form-new-ai-partnership/

Outlook

A robot that knows the next step is worth more than one that only looks impressive.

This Atlas feels like a quiet turning point. It is not flashy. It is honest about what robots can do right now. Expect careful pilots in factories and warehouses. If the robot proves reliable, we will see more sites use humanoids for tasks that need reach, balance, and humanlike motion. Over time these robots could move from show floor curiosities to shop floor tools.