Introduction: From backflips to the assembly line

Boston Dynamics made Atlas a household name with jaw-dropping demos: parkour, backflips, and choreographed routines. At CES 2026 the company showed us the next act: Atlas as a product. This version is presented not as a research platform but as a system intended for industrial use—hardware, software, data pipelines, and a production plan bundled together.

The demo mattered less than the system around it. What was announced at CES is a move toward deployable humanoids, not another viral clip.

#1 - It’s intentionally not human

Atlas looks humanoid, but Boston Dynamics has purposefully avoided slavishly copying human anatomy. The design decisions favor performance and reliability over mere likeness.

Boston Dynamics Atlas (Image credit: Boston Dynamics)

- Joints with wide rotation let Atlas take shorter, more efficient paths than a human would—useful when speed and repeatability matter.

- Recovery strategies (the way Atlas stands up, for example) are chosen for stability and uptime, not for biological plausibility.

That matters because a machine optimized for tasks will beat a machine optimized to look human in most industrial settings. Boston Dynamics is prioritizing throughput and safety over aesthetics.

“We designed Atlas’s head and face so workers understand it’s a tool, not a person.” — Boston Dynamics at CES 2026

#2 - The scale is real

This is not a soft pilot. The CES presentation laid out a production and deployment plan that aims for substantial volume.

Key points presented at the keynote:

- Hyundai and Boston Dynamics are building a new robotics factory.

- Annual production capacity cited: 30,000 Atlas units.

- The initial 2026 supply was allocated within the Hyundai Motor Group ecosystem and a named AI partner.

If those numbers hold, the project shifts the conversation from proof-of-concept to large-scale automation.

#3 - Industrial-grade hardware, not lab toys

The product-spec Atlas is engineered to industrial standards rather than lab fragility. The specs presented emphasize durability and practical capability:

- Mobility: 56 degrees of freedom with mostly rotational joints for robust motion.

- Manipulation: Human-scale hands with tactile sensing for dextrous tasks.

- Perception: 360° vision for situational awareness.

- Strength & reach: rated lift up to ~110 lb and reach to ~7.5 ft.

- Durability: water-resistant design; operating range reported from roughly -4°F to 104°F.

- Endurance: approximately 4 hours of active work with autonomous battery swap and return-to-charge behavior.

Boston Dynamics Atlas (Image credit: Boston Dynamics)

Those specifications place Atlas in the same operational category as industrial machinery rather than experimental research rigs.

#4 - AI closed the loop

Boston Dynamics has long built capable bodies. The missing ingredient for autonomous deployment was a general-purpose, multimodal AI capable of converting perception into repeatable, safe action.

At CES, Boston Dynamics announced a partnership to integrate large, multimodal models into Atlas’s stack. The stated goal: combine perception, reasoning, and action so the robot can learn and generalize factory skills rather than only executing brittle, hand-coded routines.

Put plainly: having a strong body is necessary, but not sufficient. The recent advances in general AI are what make practical autonomy plausible now.

#5 - A data factory for scale

Scaling robots requires scaled data. The partners described a data-centric approach: dedicated facilities and factory networks that generate labeled, real-world operational data to train robot skills.

- Hyundai’s global, software-defined factories are positioned as a continuous data source.

- A central training platform and application center were described to collect, curate, and iterate on that data.

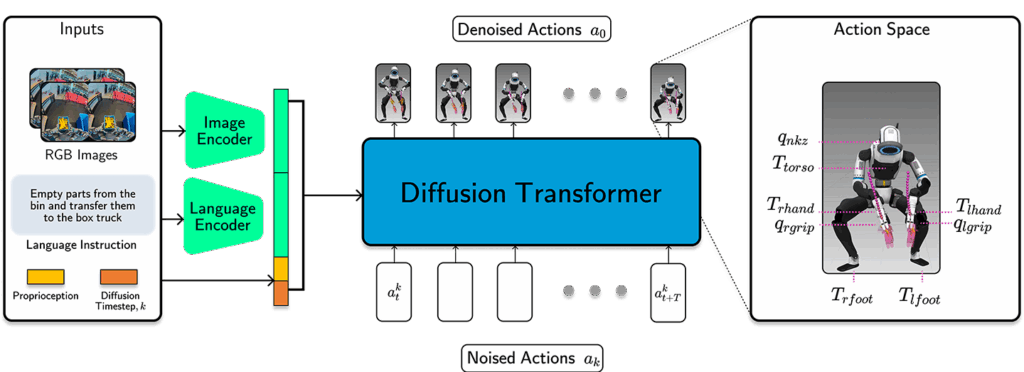

Policies map inputs (images, proprioception, and language prompts) to actions (Image credit: Boston Dynamics)

The value proposition is straightforward: proprietary, real-world data tailored to manufacturing creates a learning advantage that compounds as deployment grows.

#6 - A full-stack, three-way partnership

The announced collaboration combines three complementary capabilities:

- Boston Dynamics: physical design and control expertise—the body.

- AI partner: multimodal foundation models—the brain.

- Hyundai: manufacturing scale and operational footprint—the industrial backbone.

Together this vertical stack reduces friction across development, deployment, and continuous improvement.

Conclusion — What to watch next

CES 2026 showed a clear shift: humanoids are being packaged as products, not just research artifacts. The critical signals to monitor are real-world deployments, verifiable production numbers, safety certifications, and independent operational metrics from early adopters.

If the system works as presented, the industry will move from sporadic demos to sustained, factory-scale applications. The pace and ethics of that shift will depend on how these partners manage safety, interoperability, workforce transition, and data governance.